Heat Press machines are used to adhere vinyl to fabric- it’s how names and numbers are put on jerseys, how we can add names to screen printed shirts, and one of the most efficient ways we can put photographs on shirts (digital heat press).

We have two heat press machines, and one dedicated vinyl laser cutter for custom designs.

The heat press machines consist of two plates, the top of which is heated (usually between 300 and 400 degrees, depending on the procedure). The top plate is lowered onto the vinyl/garment and heats the vinyl until it adheres to garment. Our heat press machines are semi-automatic, which means that the top plate must be lowered manually but then the machine controls the pressure and heat for the pre-set amount of time, giving the most even and effective pressing for your garment.

Digital heat press is applied using the same method, but the vinyl is digitally printed in full color and then cut to a custom shape. This offers a great alternative for projects that require full color, in which screen print set up may be too costly for a small qty run.

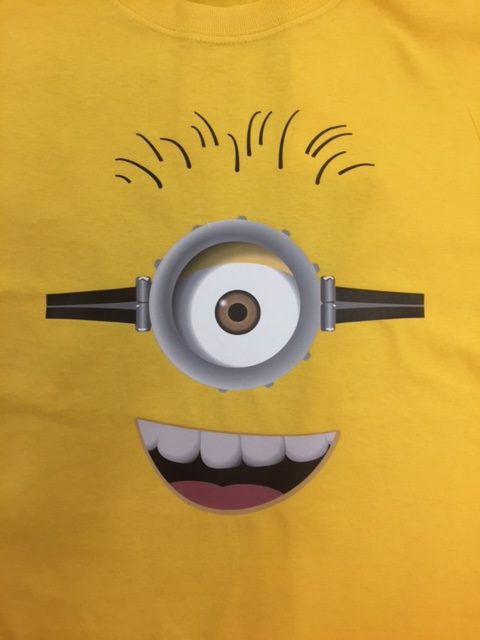

All 3 photos below are samples of heat press. The marathon shirts worn by our owners are examples of custom designed and cut heat press vinyl. The 2 minion shirts are examples of our digital-print heat press vinyl, also custom designed.

Sublimation is another decoration process that uses heat press

Dye-sublimation printing is a digital printing technology using full color artwork that works with polyester and polymer-coated substrates. Also referred to as digital sublimation, the process is commonly used for decorating apparel, signs and banners, as well as novelty items such as cell phone covers, plaques, coffee mugs, and other items with sublimation-friendly surfaces. The process uses the science of sublimation, in which heat and pressure are applied to a solid, turning it into a gas through an endothermic reaction without passing through the liquid phase.

The end result of the sublimation process is a nearly permanent, high resolution, full color print. Because the dyes are infused into the substrate at the molecular level, rather than applied at a topical level (such as with screen printing and direct to garment printing), the prints will not crack, fade or peel from the substrate under normal conditions.